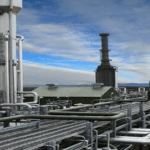

Dehydration and Mercury Removal Unit

مهر ۵, ۱۴۰۳

NGL Gas Separation Unit

مهر ۵, ۱۴۰۳Ethane Separation Unit

The Ethane Separation Unit aims to extract methane (CH4) and ethane (C2H6) from raw gas. Specifically, the feed gas specifications from Unit 104 include a pressure of 62 bara and a temperature of 27.6°C. The products of this unit comprise sweetened methane, which is sent to Unit 106 for export, ethane directed to Unit 116, and C3+ products forwarded to Unit 107.

Cooling Process

To adjust the dew point of the gas, cooling operations are necessary. This cooling takes place in the Cold Box, which consists of parallel channels. In these channels, both gas and liquid phases flow for optimal heat exchange.

Methane and Ethane Separation

In the de-methanizer column, methane separates from other fluids at an extremely low temperature of about -94°C and a pressure of 30 bar. Meanwhile, the remaining fluids, known as C2+, are pumped from the bottom of the column to the de-ethanizer column for ethane separation from C3+.

The low-temperature gas phase of methane passes through several heat exchangers. As a result, its temperature increases. Following this, a compressor increases the pressure by approximately three bars, reaching a total of 33 bar, before sending it to the gas export unit (Unit 106).

Ethane Liquefaction

After being released in the column, the ethane gas is directed to the Ethane Condenser. Here, its temperature drops, allowing for effective separation. The separated ethane is then sent to Unit 116 for CO2 removal.