Sulfur Recovery Unit: Process and Environmental Considerations

مهر ۱۱, ۱۴۰۳

Ethane Purification

مهر ۱۱, ۱۴۰۳Introduction

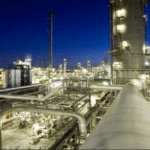

Refineries are complex industrial units that transform crude oil into valuable and usable products such as gasoline, diesel, kerosene, fuel oil, and liquefied gas. This process involves the separation and enhancement of various components of crude oil. Given the complexity of refining processes and the high importance of safety and efficiency, training skilled and specialized human resources is particularly critical. Refinery personnel must be familiar with the principles of chemical engineering, mechanics, process control, and safety to work effectively in this industry.

Refinery units are divided into three main categories:

1. Process Units

2. Utilities Units

3. Offsite Units

Process Units

These units form the core of the refinery and are responsible for converting crude oil into high-value final products such as gasoline, diesel, kerosene, and petrochemical products. Key process units include:

– 100: Gas Receiving Facilities

– 101: Gas Sweetening

– 102: Monoethylene Glycol Recovery

– 103: Gas Condensate Stabilization

– 104: Dehydration and Mercury Removal

– 105: Ethane Separation

– 106: Export Gas Sending

– 107: NGL Separation

– 108: Sulfur Recovery

– 109: Sour Water Stripping

– 110: Gas Condensate Stabilization Support

– 111: Propane Refrigeration Cycle

– 112: Gas Condensate Sweetening

– 113: Caustic Recovery

– 114: Propane Refining

– 115: Butane Refining

– 116: Ethane Refining

Utilities Units

These units provide the necessary services for the proper functioning of the process units. Key utilities units include:

– 120: Electric Power Generation

– 121: Steam Generation and Distribution

– 122: Gas Fuel Unit

– 123: Instrument and Service Air

– 124: Nitrogen Production

– 125: Sea Water Intake

– 127: Deionization

– 128: Potable Water

– 129: Industrial Wastewater Treatment

– 130: Firefighting Water

– 131: Diesel Storage Tanks and Generators

– 132: Cooling Water

Offsite Units

These units comprise ancillary facilities and equipment located outside the main area of the process units. Some of the most important offsite units include:

– 140: Flare

– 141: Waste Disposal

– 142: Fuel Pit

– 143: Storage and Dispatch of all Condensates

– 144: Liquid and Solid Sulfur Storage

– 145: Propane Storage

– 146: Chemical Storage

– 147: Propane Storage

– 148: Butane Storage

Conclusion

Training specialized and skilled personnel in refineries is one of the primary factors for success in this industry. Investing in training can lead to improved productivity, safety, and product quality in refineries. SANILCO Process Engineering Company, as a leading firm in the engineering and optimization of various industrial processes, including refineries, offers specialized and practical training services to its clients.

For more information, please contact us.