Description

Diethanolamine (DEA) is an organic chemical compound consisting of a secondary amine and a double alcohol. This binary alcohol has two hydroxyl groups. And like other amines, diethanolamine also acts as a weak base. Other names synonymous with diethanolamine include Di-ethanolamine, diethylolamine, hydroxyethyl, DEA, DELA, amine, dihydroxyethylamine and trolamine.

Monoethanolamine or MEA is a liquid organic compound with high viscosity, hydrophilic, colorless and has an ammonia-like odor. The chemical formula of this compound is H2NCH2CH2OH. This substance is widely found in living natural tissues. It is also one of the components of lecithin. This material is very important in the process of adsorption of acid gases from natural gas. And now it is known as one of the most widely used solvents in this industry.

Triethanolamine, known as TEA or TEOA. It is an organic chemical compound consisting of one group of amines and three groups of alcohols. Its chemical formula is C6H15NO3, which is an organic substance belonging to the group of oxygenated and nitrogenated hydrocarbons. Triethanolamine is mainly used in the manufacture of surfactants, liquid detergents, cosmetics, etc.

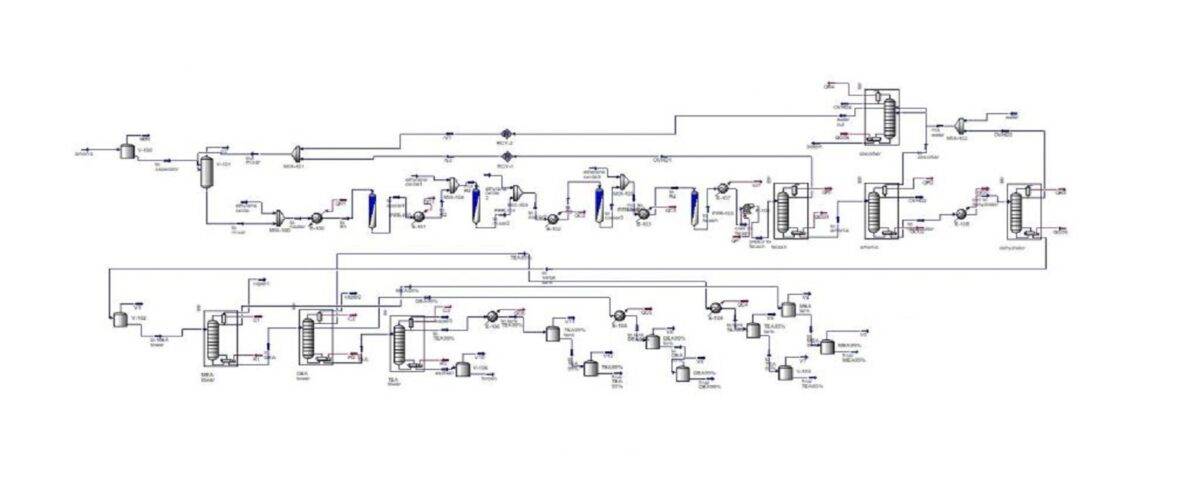

MEA, DEA, TEA Production Unit

For the production of ethanolamine chemicals, ammonia solution, returned ethanolamines and ethylene oxide are continuously and intermittently introduced into the reaction system. In this part, MEA, DEA and TEA are obtained simultaneously and under simple conditions. The production rate of each of the trustees can be different. And it depends on the correct selection of NH3 / EO ratio and the return amines from other steps.

Diethanolamine is produced from the reaction of ammonia with ethylene oxide. This process is the only production process of this material on an industrial scale. In this process, the reactions are carried out in the liquid phase and in the presence of water. And they are very exothermic. The production ratio of diethanolamine is usually controlled by the molar ratio of ammonia to ethylene oxide input to the reaction. Today, ethanolamines are produced on an industrial scale from the reaction of ethylene oxide with ammonia. This reaction is slow and adding water accelerates the reaction.

In this project, the conceptual simulation of the MEA, DEA, TEA production unit has been done from the book diagrams with the help of Aspen Hysys software.