Introduction

The design of a hexane transfer collector using SolidWorks represents a critical aspect of optimizing the transfer and storage of flammable liquids in industrial processes. This collector plays a vital role in ensuring the safe and efficient transfer of hexane, a solvent extensively employed in various chemical applications. Employing SolidWorks for this design allows for precise modeling and simulation of the collector’s components, ensuring that factors such as material choice, structural integrity, and fluid dynamics are thoroughly analyzed. By utilizing advanced features of SolidWorks, designers can create a collector that not only meets the necessary regulatory standards for safety but also enhances operational efficiency through effective fluid handling and minimal risk of leaks or spills. This process ultimately contributes to the reliability and sustainability of industrial operations involving hexane.

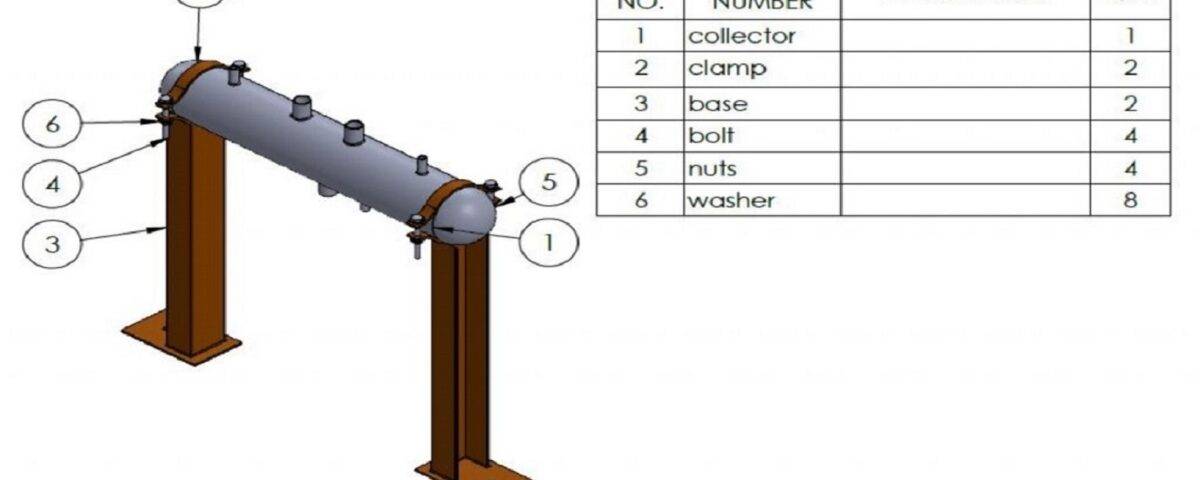

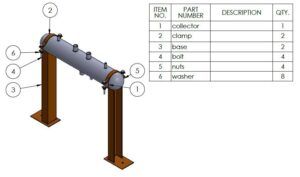

The purpose of this project is to design a hexane transfer collector made of S.S 316L. With the preparation of this project, you will be provided with 2 equipment construction diagram sheets, including Body drawing, 3D VIEW & Nuzzles Orientation Layout. The diagrams are prepared in AutoCAD file format. Solidwork files will also be available to you. It should be noted that this equipment was built in a paint and resin unit in Shiraz Industrial Township in 1995 and is in operation.

Process Description

The design of a hexane transfer collector in SolidWorks typically involves several key stages. First, the design engineer begins by defining the requirements and specifications of the collector, which include dimensions, flow volume, and environmental conditions. Next, using SolidWorks’ 3D design tools, an initial model of the collector is created, incorporating essential components such as channels and angles to optimize hexane flow.

In the subsequent stage, dynamic and empirical analyses are conducted to assess the performance of the collector, ensuring it aligns with engineering standards. Once the design is finalized, technical documentation, including production drawings and required material specifications, is prepared. Ultimately, the design must be such that it offers enhanced manufacturability and maintainability in practice, delivering optimal performance in real-world applications.

Conclusion

The design of a hexane transfer collector in SolidWorks demonstrates that this process is not only based on precise engineering and technical analysis but also requires attention to detail and adherence to contemporary industrial standards. By utilizing the advanced tools of this software, we are able to create an optimized and efficient model that effectively manages hexane flow.

Conducting necessary simulations and analyses at various stages allows us to improve the collector’s performance and mitigate potential risks. This design ultimately helps manufacturers achieve higher quality in the final product and better efficiency of liquid transfer systems, which can lead to increased productivity and reduced costs in related industries.