Introduction

The Fischer-Tropsch process is a modern technology for converting gas to liquid (GTL) that produces liquid fuels from gaseous sources, including natural gas, coal, and biomass. Given global concerns over environmental pollution and reliance on fossil fuels, examining the economic aspects of this process is of great importance.

This process can act as a bridge between non-renewable energy sources, such as coal and natural gas, and the production of cleaner liquid fuels. Additionally, by leveraging this technology, gas-rich countries can achieve energy self-sufficiency while reducing their dependence on crude oil.

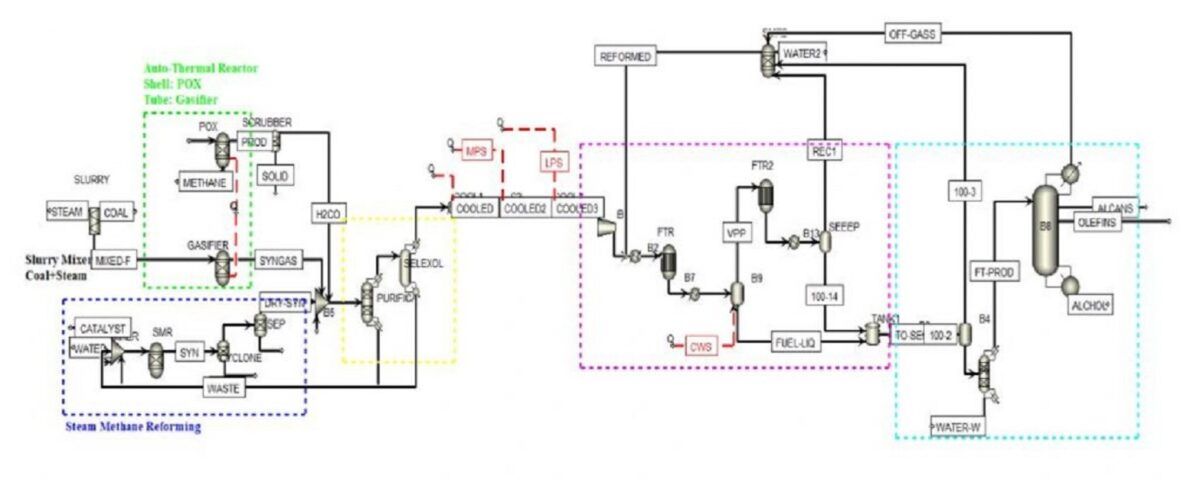

The Fischer-Tropsch process comprises several key stages: initially, natural gas or other carbon sources are converted into synthesis gas through chemical transformations. This synthesis gas is then transformed into liquid hydrocarbons in specialized reactors under specified temperature and pressure conditions. The quality and type of final products depend on the process conditions and the catalysts used. Furthermore, this process can facilitate the production of various fuels, including diesel, gasoline, and basic chemicals required in the chemical industry.

For instance, a techno-economic analysis presented in related literature investigates the production costs of Fischer-Tropsch synthetic fuels and waxes with a carbon number of C20+ from the gasification of anaerobic digestion waste in a dual fluidized bed gasifier. Results indicate that utilizing digested waste has advantages over woody biomass, achieving a maximum plant efficiency of 56.3% through waste utilization and off-gas recirculation.

Process Description

This analysis encompasses gasification, synthesis gas production, and the main Fischer-Tropsch process, each with its specific expenses. Additionally, factors such as energy costs, raw material supply, and catalyst expenses significantly impact the economic viability of this process.

Revenue from the sale of final products and the market potential for utilizing clean fuels must be compared with production costs.

The economic analysis of the Fischer-Tropsch process also includes assessing political and environmental factors that may influence the implementation and profitability of these projects. Additionally, the availability and access to primary resources, such as coal or natural gas, can affect production costs and final pricing.

Technological advancements that improve catalyst efficiency and conversion processes may reduce operational costs and thus enhance the economic appeal of this process.

Economic Assessment and Feasibility Study of Syngas Production and Fischer-Tropsch Process

Conducting feasibility studies and economic calculations before starting any business or plant is essential. It provides various options related to the desired business and may even lead to the elimination of some previous plans, resulting in savings in costs and time. Additionally, the shortage of fuels, particularly gasoline, which is one of the most important petrochemical and refining industries in Iran, has increased the significance of this issue. This section focuses on conducting a feasibility study for syngas production and the Fischer-Tropsch process, including the calculation of Total Capital Investment (TCI) and Fixed Capital Investment (FCI).

Conclusion

The economic evaluation of the Fischer-Tropsch process indicates that, despite facing hurdles such as high operational costs and dependence on raw material prices, this technology presents considerable promise for advancing a sustainable energy future. As the world increasingly focuses on minimizing greenhouse gas emissions and meeting the growing need for clean fuels, the Fischer-Tropsch process stands out as an attractive solution both economically and environmentally.

Technological advancements and supportive policies can reduce production costs and improve the economic returns of this process. Overall, the future of the Fischer-Tropsch process depends on numerous factors that require continuous analysis and evaluation to maximize its benefits effectively.