Introduction

Due to the high cost of perfluorinated membranes, hydrocarbon membranes such as sulfonated poly(ether ether ketone) or sulfonated polysulfone have attracted significant attention from researchers for use in polymer electrolyte membrane fuel cells. Therefore, investigating their performance, chemical durability, and mechanical stability is crucial for their commercialization. A review of literature and experimental studies has revealed that numerous researchers have conducted notable studies on the mechanical and chemical degradation of both perfluorinated and hydrocarbon membranes used in polymer electrolyte membrane fuel cells in recent years.

Consequently, valuable insights can be gained from these experimental studies. Additionally, the chemical and physical properties of the materials used in these studies can be utilized to model the mechanical degradation of hydrocarbon membranes. Furthermore, numerous significant modeling studies have focused on the mechanical degradation of perfluorinated membranes, such as Nafion. Thus, these modeling studies can serve as suitable templates for modeling mechanical degradation in hydrocarbon proton exchange membranes.

COMSOL Modeling of Hydrocarbon Proton Exchange Membranes for Fuel Cell Applications

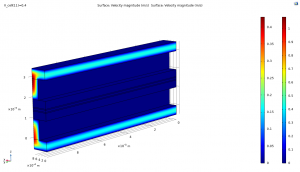

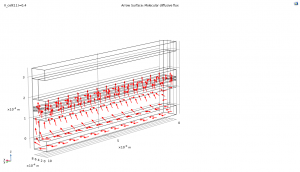

In this project, the mechanical degradation of hydrocarbon proton exchange membranes for fuel cell applications has been modeled using COMSOL software. The following images present a portion of the simulation results.

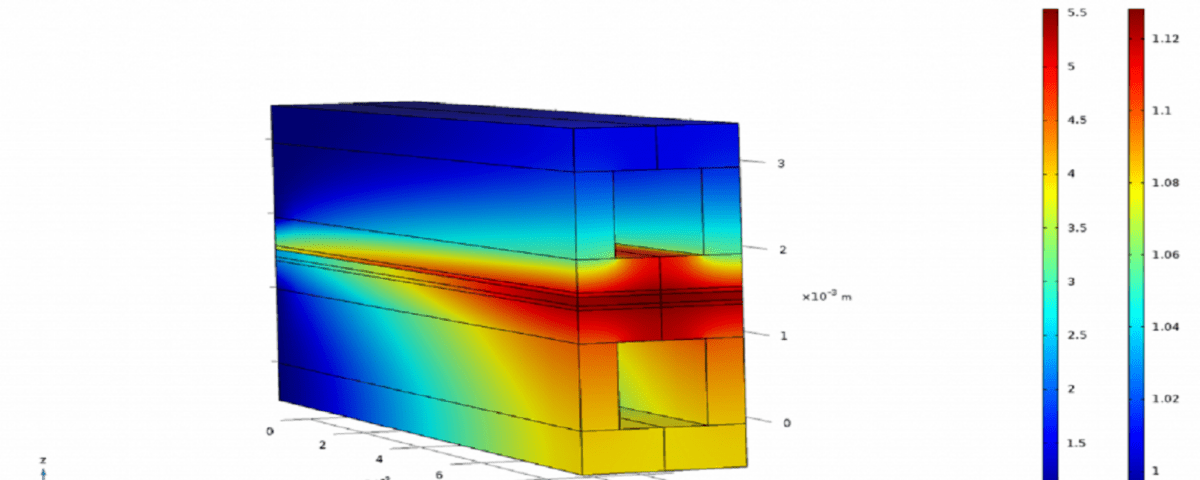

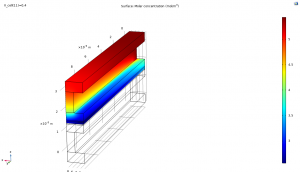

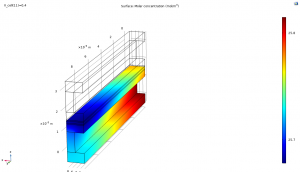

Oxygen at the Cathode

Hydrogen at the Anode

Velocity Profile

Mass Transfer Flux

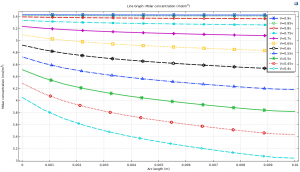

Concentration at Different Voltages