Introduction

The emission of greenhouse gases from the combustion of waste rubber significantly contributes to global warming, making the need for alternative technologies for the reuse of these tires essential. One promising method is the gasification of waste tires, where shredded tires are combined with steam or oxygen to produce syngas and by-products such as char. This process can lead to the generation of valuable fuels and activated carbon (AC).

Process Description

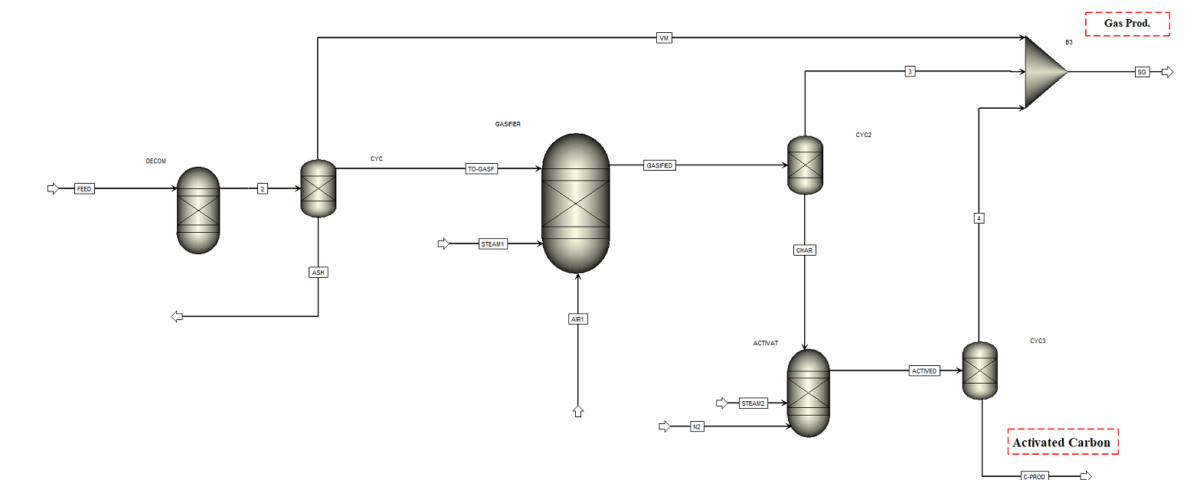

In this project, the gasification process of waste rubber is divided into two main areas: the pyrolysis zone and the gasification zone. In the pyrolysis zone, rubber is thermally decomposed into its primary components, including light gases, solid carbon, and ash. This stage is modeled using an RYield reactor in Aspen Plus. The produced solid carbon is then transferred to the gasification zone.

In the gasification zone, modeled by the RGibbs reactor, combustion and reduction reactions occur, resulting in the production of syngas. The composition of the outlet gases from this area depends on parameters such as the equivalence ratio (ER) and steam-to-fuel ratio (SFR). These reactions take place at a temperature of 800 degrees Celsius and a pressure of one bar.

Process Simulation

The simulation of the waste rubber gasification process using Aspen Plus is based on data from literature. In this simulation, rubber is introduced as a non-conventional solid at temperature and pressure conditions of 25 degrees Celsius and one bar. The simulation model includes four main blocks:

1. Decomposition Block: In this stage, rubber decomposes into light gases, solid carbon, and ash. This process is modeled using the RYield reactor and a cyclone model to separate solid products from the produced gases.

2. Calculator Block: This block is used to calculate hydrocarbon production in the fluidized bed reactor. These calculations are based on semi-empirical models available in scientific literature.

3. Gasification Block: This block is modeled using the RGibbs reactor, and the chemical reactions in this stage reach chemical equilibrium. The gasification temperature is set at 800 degrees Celsius and the ER and SFR ratios are optimized in this stage.

4. Activation Block: In this stage, the carbon produced from gasification reacts with steam and pure nitrogen to produce activated carbon. The goal of this stage is to increase the specific surface area of the carbon (porosity) for various applications.

Fundamental Assumptions

To simplify and expedite the simulation, several fundamental assumptions are made:

– The gasification zone operates isothermally and under steady-state conditions.

– Pressure throughout all process areas is considered to be atmospheric pressure (1 bar).

– Pressure drop in reactors is neglected.

– Tar formation is ignored in the process.

– Drying and segregation of materials occur instantaneously and simultaneously.

– Reactions reach chemical and phase equilibrium.

– Thermal losses from gasifiers are disregarded.

Results and Analysis

In this project, the performance of the process is evaluated using various metrics such as syngas yield (Yg), carbon conversion ratio (CCR), and cold gas efficiency (CGE). These metrics serve as indicators for assessing the efficiency and productivity of the gasification and carbon activation processes.

Conclusion

The simulation of waste rubber gasification using Aspen Plus is a powerful tool for investigating and optimizing this process. Through this simulation, suitable operating conditions can be determined for producing syngas with high yield and quality. Additionally, the production of activated carbon with a high specific surface area is another advantage of this process, which can be utilized in various industries.

Simulation of Waste Rubber Gasification Process in Aspen Plus

In this project, the simulation of the waste rubber gasification process for the simultaneous production of syngas and activated carbon using Aspen Plus is conducted based on the methods and data from literature, focusing on the analysis and optimization of operational parameters.