Introduction

The simulation of the natural gas dehydration unit at the Farashband refinery using Aspen Plus. represents a significant step towards optimizing the efficiency and reliability of gas processing operations. Dehydration of natural gas is essential for removing water vapor and preventing issues such as hydrate formation and corrosion within pipelines. By leveraging Aspen Plus, engineers can create accurate models of the dehydration process, taking into account various factors including temperature, pressure, and specific absorption techniques.

This simulation enables the analysis of different operational scenarios and the evaluation of various dehydration technologies, such as glycol methods or molecular sieving.

Process Description

Initially, suitable thermodynamic models are utilized to identify the physical and chemical properties of the natural gas and unwanted components. The simulation allows engineers to analyze the unit’s performance under different conditions, identify weaknesses, and implement necessary optimizations to enhance efficiency and reduce costs. This process also assists in simulating and predicting system behavior under unusual conditions or variable loads.

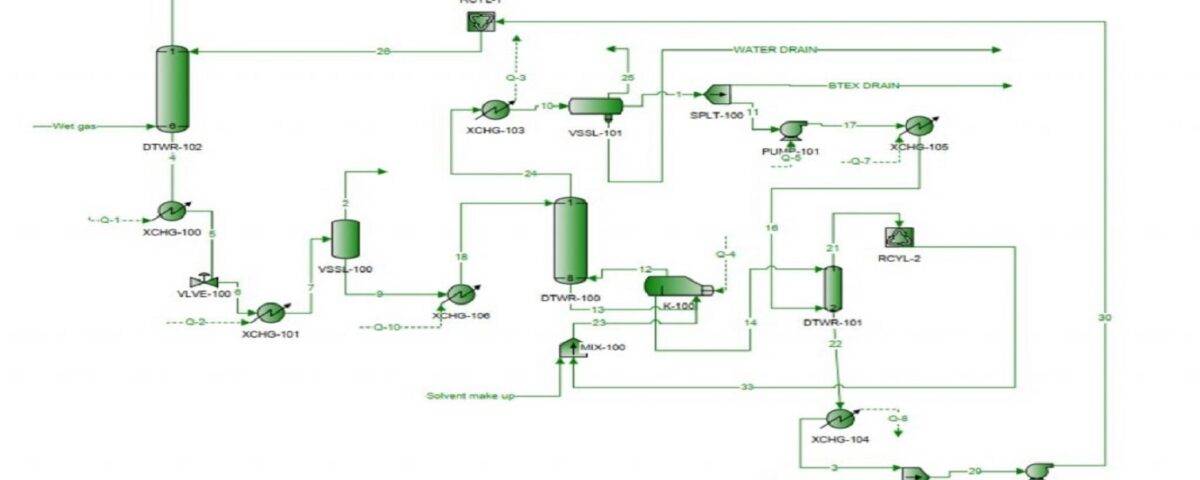

This unit, which is known as “DRIZO” or “AGHAR” in the refinery, performs dehumidification with the help of TEG. The simulation is done in Aspen Plus software and has a video report (educational video) for 25 minutes. The simulation data has been made from several theses with the same titles, and all the files will be sent to you after purchasing this project. In this unit, different solvents have been used for reduction and adsorption, so this simulation has 4 main files (N-C7, i-C8, Toluene and a file without DRIZO). It should be noted that all the information in the said thesis was recorded from Farashband-Dalan Refinery in DRIZO Unit.

You can see the final simulated file in general mode as below.