Introduction

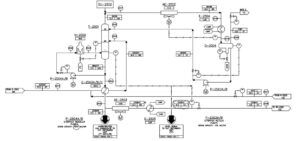

The simulation of the T-2501 tower at the Borzouyeh Petrochemical Company using Aspen Plus is a key step in the analysis and optimization of chemical and petrochemical processes. The T-2501 tower, as an essential component of the petrochemical product separation unit, is responsible for separating various compounds. Utilizing Aspen Plus allows engineers and researchers to simulate the tower’s behavior under different operational conditions, enabling a more detailed analysis of its performance. This simulation not only aids in identifying the system’s strengths and weaknesses but can also lead to optimizing energy consumption and increasing production efficiency. By leveraging accurate modeling in Aspen Plus, better predictions of operational outcomes can be made, along with the identification of the optimal operating conditions for the T-2501 tower.

Description

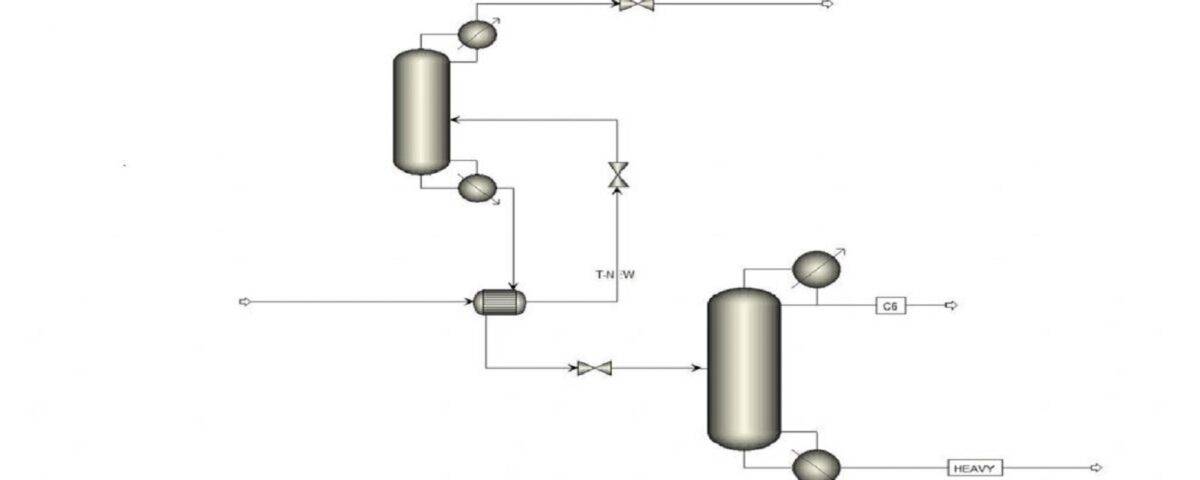

In Unit 250 of the Nouri Petrochemical Company, the feed of Tower T-2501 comes from Drum 2502, which contains gaseous condensates. This stream includes both light and heavy hydrocarbons. The objective of Tower T-2501 is to separate the light components (C-1 to C-6). After separating the light components in the first tower, the bottom products are sent to Unit 300 (reforming) for cracking.

In this project, to separate C6 hydrocarbons, a new secondary tower has been designed. Before entering the reforming unit, cyclohexane, normal hexane, and benzene are separated in this new tower. The figure below shows the PFD of Tower 2501 in BORZOUYEH Pet. Co. Company. The bottom outlet of the tower is added to the newly designed secondary tower.

Conclusion

The conclusion drawn from the simulation of the T-2501 tower at the Borzouyeh Petrochemical Company using Aspen Plus highlights the importance of modeling in optimizing industrial processes. This simulation facilitates a detailed examination and analysis of the tower’s performance under various conditions, which can contribute to cost reduction and increased efficiency. The results obtained from the simulation can serve as effective guidance for engineering decisions regarding the optimization of the tower’s design and performance. Additionally, this approach aids in identifying critical points and improving processes, ultimately leading to enhanced quality and productivity in the petrochemical unit. Therefore, the application of advanced technologies such as Aspen Plus can be considered an essential tool in the petrochemical industry for enhancing performance and achieving economic objectives.

This project is simulated with Aspen Plus software and has an educational video.