Aspen Hysys Simulation of MEROX Unit

مهر ۵, ۱۴۰۳

Propane Purification Unit

مهر ۵, ۱۴۰۳Unit 115, Phases 9 and 10 of South Pars (butane sweetening by Sulforex method)

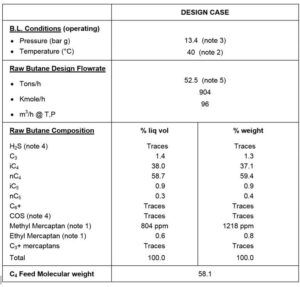

At the entrance of unit 115, sour butane has the following percentage composition:

(the entrance of the unit does not contain carbonyl oxide and only contains methyl mercaptan and ethyl mercaptan)

Unit description

Unit 115 has a butane extraction tower with 15 trays. Methyl mercaptan and ethyl mercaptan are converted into mercaptide according to the reaction (1). Sour butane enters from the bottom of the tower and is mixed with the incoming caustic solution from unit 113 (caustic recovery unit), which has 100 ppm wt LCPS-30 catalyst (which is injected into the system in liquid form in unit 113), in a liquid-liquid form. is in contact.

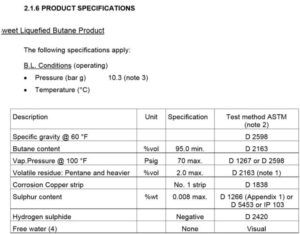

Sweetened butane

Then the sweetened butane enters the precipitator and it is washed with water after entering it. and finally after passing through the sand filter to prevent the caustic solution from coming out along with the sweetened butane, it enters the butane dehumidification unit.

Of course, a part of the sweetened butane is divided before entering the butane dehumidification unit and a part of it is sent to the caustic recovery unit. Butane dehumidifier works like propane dehumidifier. It should be noted that the simulation of Sulforex Unit 114 in South Pars has been done in Hysys software.

2 Comments

It was great

thank you