Introduction

Chlorine-Alkali process is one of the most important industrial processes. which is used for the electrolysis of salt solution (sodium chloride or NaCl) in order to produce basic chemicals such as sodium hydroxide, chlorine and hydrogen. This process is very important in the chemical industry due to the wide production and wide application of these materials. Sodium hydroxide is one of the most widely used chemicals used in various industries such as paper production, soap, and detergents.

The Chlorine-Alkali process was first developed on an industrial scale in 1892. and quickly established its position as one of the main methods of chlorine and sodium hydroxide production. In 1987, about 35 million tons of chlorine were produced through this process. which shows the importance and extent of using this method on a global scale.

This process mainly uses sodium chloride aqueous solution as raw material. In addition to sodium chloride, if other solutions such as calcium chloride or potassium chloride are used as feed. Products will contain calcium or potassium respectively. Also, there are similar processes that convert liquid hydrogen chloride into hydrogen and chlorine or molten sodium chloride. are converted into metallic chlorine and sodium.

Description of The Process

The process of producing sodium hydroxide by Chlorine-Alkali method includes the electrolysis of sodium chloride solution in water. This process is done as follows:

1. Feed: sodium chloride solution (NaCl) is introduced into the system as feed. This solution usually has a concentration of 30% to 35% by weight.

2. Electrolysis: the solution enters the electrolyzer. Electrolyzer is divided into three main types:

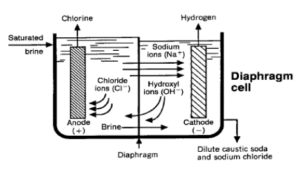

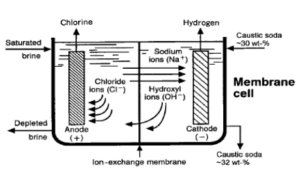

Diaphragm Cell: In this type, a diaphragm is placed between the anode and the cathode, which prevents mixing of the products, but allows Na+ ions to pass through.

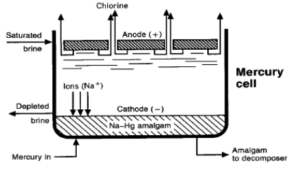

Mercury Cell: In this type, mercury is used as a cathode and reacts with sodium metal to form sodium amalgam. This method is very energy-consuming and harmful and is rarely used today.

Membrane Cell: In this method, a membrane is used that allows Na + ions to pass through. But it prevents the passage of -Cl ions. This method is usually the most optimal and least risky method.

1. Reactions: In the electrolyzer, Na + ions move to the cathode and Cl – ions move to the anode. At the cathode, water decomposes. and hydrogen and sodium hydroxide (NaOH) are produced. At the anode, -Cl ions are converted to chlorine gas.

2. Products:

Hydrogen gas is produced at the cathode.

Sodium hydroxide is also produced in the cathode and is intended as the main product.

Chlorine gas is produced in the anode, which can be used as a byproduct.

3. Concentration and separation: The sodium hydroxide solution from the electrolyzer is sent to the concentration and separation sections. In these parts, excess water is evaporated and sodium hydroxide is obtained with a higher concentration. Also, hydrogen and chlorine gases are separated and compressed.

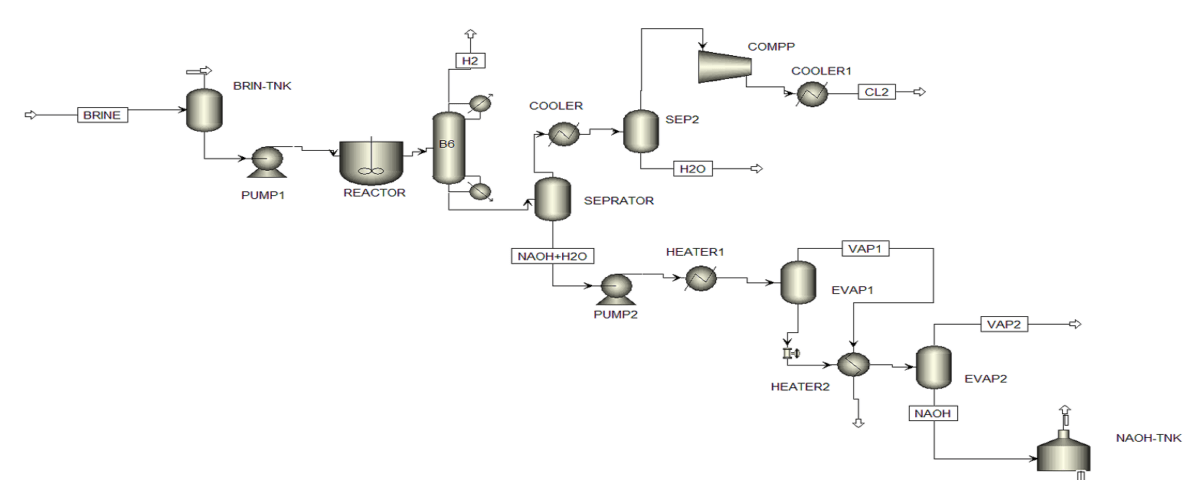

Simulation Description

ASPEN PLUS software has been used to simulate the Chlorine-Alkali process. The simulation steps are as follows:

1. Definition of Raw Materials: First, raw materials such as sodium chloride, water, hydrogen, chlorine and sodium hydroxide are defined in the software. These materials are considered as feed and process products.

2. Selection of The Thermodynamic Model: due to the presence of electrolytes and ionic reactions in the system, the ELECNRTL thermodynamic model has been selected. This model can well predict the phase balance and ionic behavior of the system.

3. Electrolyzer Modeling: The electrolyzer is simulated as the heart of the process. In this simulation, a CSTR reactor is used to model the electrolyzer, where the electrolytic reactions are defined with appropriate conversion percentages.

4. Peripheral Equipment: After the electrolyzer, peripheral equipment includes two-phase separators for gas and liquid separation, evaporators for concentrating sodium hydroxide solution, and compression units for hydrogen and chlorine gases. These equipments are essential for refining and preparing final products.

5. Analysis and Optimization: After running the simulation, the obtained results are analyzed. Parameters such as product flow rate, purity, and energy consumption are checked and, if needed, changes in operating conditions and equipment design are applied to achieve the best performance.

Conclusion

The simulation performed in this project has provided a comprehensive view of the sodium hydroxide production process. and has helped to determine the optimal operating conditions for processing products. This simulation was done assuming sodium chloride solution with a flow rate of 1300 kg/hour and a concentration of 315 g/liter. and manufactured products including 496 kg of sodium hydroxide. 97.16 kg of chlorine gas and 5.4 kg of hydrogen gas per hour are of high purity. The results of this simulation can help to optimize the process and reduce energy consumption.

Design and Simulation of Chlorine-Alkali Process by Aspen Plus

In this project, a hypothetical chlor-alkali unit with the aim of producing caustic soda and chlorine gas by-product has been conceptually designed using the process knowledge available in handbooks and articles. This design includes the selection of the main process equipment in the unit and product separation. After the conceptual design of this unit, it has been simulated using Aspen plus V10 software. The project includes full simulation and reporting to better understand the process and analyze the results.