Introduction

Propylene (C₃H₆) plays a critical role as the second most important base material in the petrochemical industry, contributing to the production of various industrial and polymer products. This unsaturated hydrocarbon, composed of three carbon atoms and six hydrogen atoms with a carbon-carbon double bond, has broad applications in petrochemicals. Known as the “caviar of the petrochemical industry,” propylene ranks just behind ethylene in base product consumption and is predominantly used in the manufacture of polymers and diverse products such as polypropylene, propylene oxide, and acrylonitrile.

As of 2018, global propylene production capacity reached 128 million tons, with an actual production volume of around 105 million tons, reflecting a worldwide production efficiency of approximately 82%. This high production level underscores propylene’s significant industrial value.

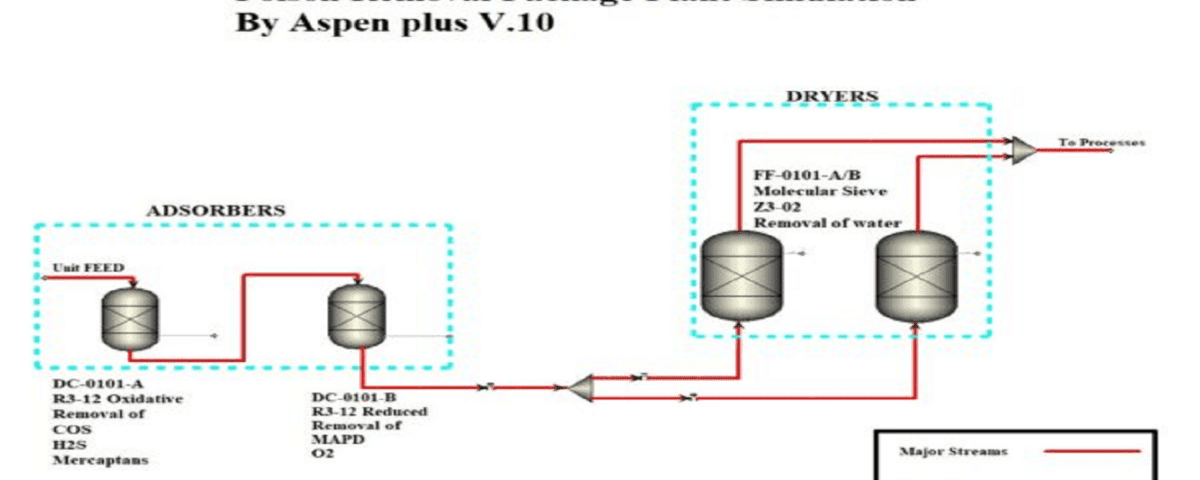

Importance of the Decontamination Process in Propylene Production

During propylene production processes—especially in methods involving naphtha cracking or olefins production units—impurities such as sulfur, oxygen, and nitrogen are commonly present in the composition. These impurities can adversely affect the quality of the final product and disrupt downstream processes. For this reason, decontamination units are essential for removing unwanted compounds, thus enhancing the quality of propylene.

Simulation of the Propylene Decontamination Process with Aspen Plus

Aspen Plus, one of the most advanced simulation tools in the chemical and petrochemical industries, enables engineers to model complex processes like propylene decontamination with high precision. This simulation, using accurate and relevant data, can aid in process optimization and reduce production costs. In this project, a simplified model of the propylene decontamination unit has been simulated using reliable data provided by BASF, Germany.

Simulation Features

- Detailed Process Modeling: Aspen Plus allows users to analyze and adjust all critical factors affecting the decontamination process, including temperature, pressure, and flow rates.

- Use of Real Data: This simulation incorporates BASF’s verified industrial data, enabling result validation and comparison with operational data.

- Energy Consumption Optimization: Aspen Plus calculates and optimizes energy usage at each stage of the process, thereby lowering costs and enhancing production efficiency.

Applications and Benefits of Propylene Decontamination Unit Simulation

- Improved Final Product Quality: Simulation and precise parameter adjustments facilitate effective impurity removal, achieving a purer propylene product.

- Cost Reduction and Enhanced Efficiency: Through accurate simulation, the decontamination process can be optimized, which in turn reduces operational costs.

- Continuous Analysis and Optimization: Aspen Plus enables continuous updates and optimizations of the process under varying operational conditions.

Conclusion

Simulating the propylene decontamination unit with Aspen Plus serves as an efficient and specialized tool for improving propylene production quality and performance. The results of this project demonstrate that with precise adjustment of operational parameters, optimal quality can be achieved while reducing energy and production costs. This simulation is highly valuable for petrochemical companies seeking innovative solutions to increase production efficiency.